INNOVATION

Enormous carbon fiber tube crafted at Purdue will support future hunt for discoveries at CERN

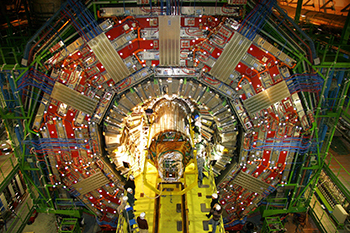

This prototype tube is part of the “High-Luminosity LHC upgrade of the CMS detector” project which is jointly funded by the Department of Energy and the National Science Foundation. The Compact Muon Solenoid (CMS) Collaboration is one of the largest scientific collaborations which includes over 4,000 scientists across the globe together in a quest to advance humanity’s knowledge of the most fundamental laws of our Universe. Purdue University is one of over 200 universities and institutes world-wide that take part in the CMS collaboration.

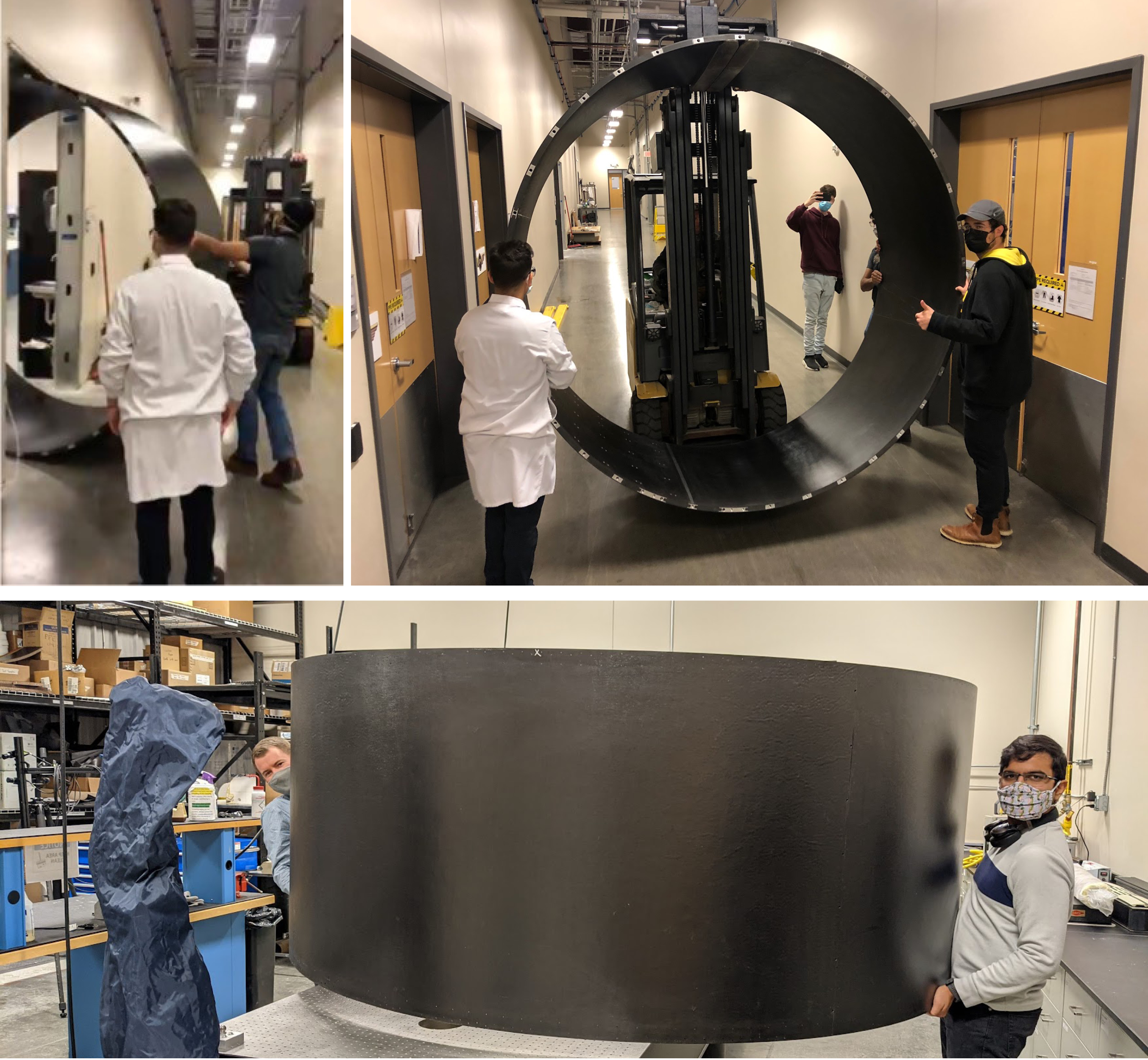

Most recently, Purdue researchers in the Purdue Silicon Detector Lab (PSDL) and the Composite Manufacturing & Simulation Center (CMSC) have worked together on the challenge of removing 35kW of heat relying on lightweight composite tracker support structures. They have been creating prototype cylinders made of carbon fiber composites and have now officially created a working prototype that will be installed and tested at CERN near the end of 2022. Purdue CMS scientists currently work on more testing, metrology, loading scenarios, and once completed prepare the eventual shipment to CERN for more tests. Once the BTST prototype arrives at CERN and has been tested, the Purdue CMS team will work on design and manufacturing of the final full-length, 5.3m (16.4ft), structure between 2022-2023. This build will rely on an external fabrication partner given the enormous size of the structure.

According to Andreas Jung, Associate Professor of Physics and Astronomy, Purdue University is particularly able to construct this type of carbon fiber prototype. Building these prototype structures made of carbon fiber requires clean-room like practices. The fibers require special handling because they are electrically conductive and need to be contained and cleaned off of all surfaces.

“Without the special capabilities at the Composite Manufacturing & Simulation Center this project would not be possible,” says Jung. CMSC is partnering with PSDL to engineer and fabricate at least 6 other unique support structures for the CMS LHC upgrade, varying in scale from a few millimeters to 3m in length. “The Purdue Silicon Detector Lab provides expertise on measurements for thermal conductivities, and other physics properties, which are essential to allow for the required thermal performance of the system.”

These composite support tubes are made of carbon fiber because it is light weight, but yet stiff, strong, withstands radiation, and has low Z (number of protons). According to Jung, carbon fiber is the de-facto gold-standard for experimental physics detector support structures.

This work may also have industrial benefits as well. According to Jung, the “airplane and space industry are the prime application, with similar demands for extremely lightweight composite structures providing stiffness and stability in view of large supported masses. Wind turbine blade manufacturers might also benefit.”

This project involves funding at the level of around $1.6 million in order to deliver a final BTST structure. Locally, this project involves many people across several disciplines at Purdue University. Notably, Ben Denos (co-PI on the project), Justin Hicks (Postdoc at CMSC), Lucas Richardson (Staff Engineer at CMSC), Jack Wheeler (Research Technician at CMSC), Sushrut Karmarkar (Phd student, CoE), Souvik Das (Physics staff), and Abraham Koshy (PhD student, CoS) are involved in the making of this prototype and related projects as well as many undergraduate students, REU students, exchange students, and nine students who have participated in the Dortmund exchange (since 2018).

Photos provided by the Jung group

Contributor: Dr. Andreas Jung

Writer: Cheryl Pierce