About the Facility & Services

The Purdue University 3D X-Ray Microscope Shared User Facility was launched in December 2017. The acquisition of the Zeiss Xradia 510 Versa 3D X-ray Microscope was supported by the EVPRP Major Multi-User Equipment Program 2017 at Purdue University. The equipment is available to all researchers on campus and external to Purdue University (Academic and Non-academic), and we accept research collaborations in all areas.

The Facility is managed by Dr. Laura Pyrak-Nolte with the assistance of Super Users who implement 3D imaging tomographic recipes and perform all scanning and analysis of the resulting 3D imaging data. To ensure that we provide the best data possible, we generally utilize in-house fabricated sample holders which improve sample positioning and data-registration abilities especially for situations where time-dependent scanning is needed.

We recommend that any researcher interested in 3D X-Ray imaging to connect with us for a consultation so you can decide if the Zeiss Xradia 510 Versa 3D X-Ray Microscope is the best for your research needs.

Click here for information on available equipment and sample requirements.

|

Dr. Laura Pyrak-Nolte 3D XRM Facility Manager Distinguished Professor Department: Physics & Astronomy Office: PHYS 164 Phone: (765) 494-3027 Email: ljpn@purdue.edu Website: Rock Physics Group |

|

Chven Mitchell Super User PhD. Student - Rock Physics Group Department: EAPS Email: mitch240@purdue.edu

|

|

Liyang Jiang Super User PhD. Student - Rock Physics Group Department: Physics Email: jiang352@purdue.edu |

|

Ben Denos Super User for CMSC Postdoctoral Researcher Department: Composites Manufacturing & Simulation Center Email: denos@purdue.edu Website: CMSC Group |

- The trainee must complete and sign both (i) the liability form and (ii) the account information form prior to the initiation of training. The hourly training rate covers set-up and initiation of the scan and post-scan finalization and validation of the scan. On average, each of the three training session will last approximately 3 hours (at the Training rate) plus the scan time. During training scans, the cost for X-ray scanning time will be billed at the Self Scan hourly rate. The training and scan time may vary based on the complexity of the scan among other factors. The center staff retains the right to require additional training if the user is deemed not fully competent after 3 training sessions.

- The analysis rate applies to requests for additional analysis of the scans (e.g. segmentation, porosity analysis, etc) performed by the center staff.

See Scanning FAQS for additional information.

Internal (Purdue University and affiliated researchers) Rates & Reservations

- Image the pore spaces within a mass of fat crystals

- Image the defects accumulated within stainless steel after cyclic loading

- 2D imaging of time-dependent crack formation within geo-architected rocks

- 3D imaging of crack formation after 3-point bending and other deformation

- 3D measurement of precipitate build up after flow experiments

- 3D imaging of 3D printed steel to evaluate deposits within pore spaces

- 2D & 3D imaging of specimen during in-situ tensile/compression testing using a Debens Testing Stage (Ask us about this equipment)

- 3D & 2D measurements of fluid movement in materials and microfluidic devices

- 3D measurement of induced cracks, and drying-induced damage to geo-architected rocks

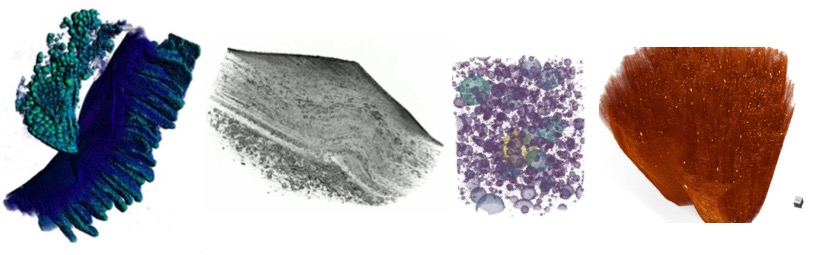

- Fiber thickness and density measurements from 3D imaging of the fabric of different types of fibers (ceramic, glass, wood, steel, etc.) in different configurations (packed, pressed, woven, mats)

- 3D imaging of fractured surfaces and roughness in 3D printed rock analogs

- 3D analysis of 3D‐printed hardened cement paste (hcp) elements, to evaluate the heterogeneous interfaces fabricated with novel architectures

- Detection and analysis of fractures in trabecular bone

- Evaluation of aggregate distribution and porosity of concrete and cement mortar cores

- 3D measurement of porosity in Sandstone and shale cores

- 3D carbon fiber orientation, foliations, and inter-connected network properties

- 3D imaging of cement boreholes

- Scout, Scan, and Zoom for samples where large FOV and high-resolution image datasets are needed

- Imaging grain displacement and particle crushing

- Compacted soil

- Pore structure of Pharmaceuticals

Agronomy

Bio-Medical Engineering

Civil Engineering

Composites Manufacturing and Simulation Center at Purdue University

Earth, Atmospheric, and Planetary Sciences

Mechanical Engineering

Materials Science Engineering

Physics and Astronomy

- If scanning and/ image analysis and segmentation were performed by any of the 3D XRM personnel please acknowledge as follows:

- If all scanning and image analysis was self-run, please acknowledge as follows:

We do accept scanning request from external clients (researchers at institutions external to Purdue University both academic and non-academic). At current we are not allowing external users to utilize the 3D X-Ray Microscope for self-scanning.

When requesting services an external user can only make a requested for Exploratory Analysis, Exploratory Scans, or Scan provided (See Services for more information). Please feel free to contact us for more information or for a 3D X-Ray Imaging consultation.

Scanning Rates for External Entities |

|

| Scan Provided (per scan hour) | $52.00 |

| Exploratory Analysis (per set-up and/ scan hour) | $63.00 |

Department of Physics & Astronomy

Department of Physics & Astronomy

Department of Physics & Astronomy

Interested in 3D X-Ray Imaging. Explore our Publications before you go.