Chattering dust allows scientists to see how fluids flow through rock

2020-10-19

Writer(s): Cheryl Pierce

The modern energy economy and environmental infrastructure rely on the flow of fluids through fractures in rock beneath the Earth’ surface where it may be out of sight but never out of mind. The human race relies on the availability of fresh water to drink, the power of fossil fuel to drive our machines, and geothermal resources to heat and cool our homes. But finding what direction these fluids take underground is hard because the fractures they follow are invisible inside opaque rock. Now, scientists at Purdue University are applying a different sense than sight to the problem. What if, instead of seeing the flow of fluids, they hear them?

Dr. Laura Pyrak-Nolte of the Department of Physics and Astronomy at Purdue University along with a team of scientists, including undergraduate Alan Wright and Dr. David Nolte also from Physics and Astronomy have published an article in Nature Communications where they test “chattering dust” to chart the path of liquids as they flow through fractures.

Chattering dust? That’s right. This dust “speaks” to the scientists and tells them where the liquids are flowing.

This team of scientists applied chattering dust, or chemically reactive grains of sucrose containing pockets of pressurized carbon dioxide gas, to study rock fractures. As the grains of the dust dissolve in the liquid that is carrying it, the pockets carrying the compressed gas burst open and emit acoustic signals. These signals can be detected using ultrasonic sensors outside the fracture allowing the movement to be tracked throughout the fracture systems. This dust is able to be heard with sensors when visual opportunities are not possible.

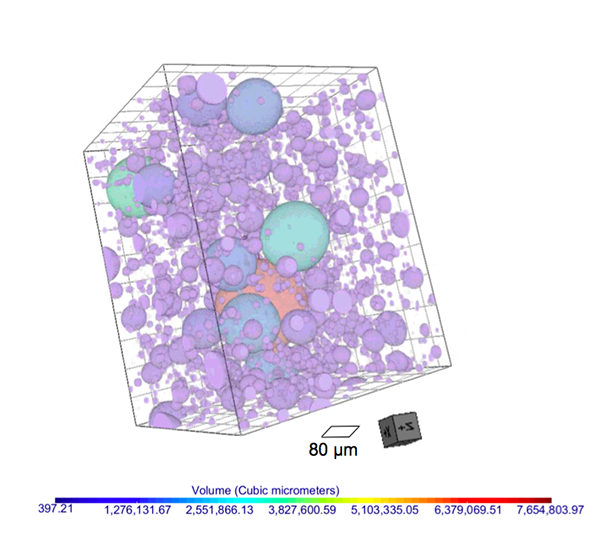

3D X-ray tomographic reconstruction of a subregion of a single “chattering” dust grain showing bubbles of compressed gas. The red bubble has a diameter of 243 micrometers (~0.0096 inches).

The speed of the “chatty” dust grains not only tells the scientists about the map of the fracture flow paths, but also how quickly the liquid is flowing. This provides information about the rock’s internal fracture geometry, and any bottlenecks that may be present in the flow paths. With current fracture monitoring systems, these bottlenecks remain unseen and cost time and money. Therefore, the chattering dust may create great savings in this modern energy economy while being kind to the environment.

“In the past, the dream for subsurface characterization was the idea of ‘smart’ dust- sensors that would flow through a rock formation and change in response to pressure or fluid chemistry as they flowed between boreholes,” says Pyrak-Nolte. “While ‘smart’ dust would demonstrate that two boreholes were connected, they provided no information on how they traveled between the boreholes. So instead of ‘smart’ dust, I thought we needed ‘chattering’ dust- dust that ‘speaks’ or makes ‘noise’ to tell us where it is as it travels.”

According to the publication titled Probing Complex Geophysical Geometries with Chattering Dust, “chattering dust takes advantage of the well-developed field of acoustic emission and induced seismicity, hence using chattering dust for laboratory experiments on rock enables more complex systems to be studied than is possible using X-ray or optical imaging. Currently, there are no other methods that can determine the flow field lines in opaque materials such as rock or the direction of flow through more complicated fracture networks in rock cores or other geotechnical laboratory samples.”

Using this chattering dust has distinct advantages over other commonly used practices. One common practice is to use chemical sensors, but these chemical sensors must be collected after the testing. With chattering dust, there is no need to collect the dust after use because it simply dissolves away to nothing. Another common method uses passive tracers like dyes that can only say whether two fractures are connected. Chattering dust is preferable to these passive tracers because it charts the actual transport path of the fluids to say how the fractures are connected.

Pyrak-Nolte states, “the next step for us is to go bigger.” Their team believes that the work they have conducted in the lab has been so successful that chattering dust has the potential to scale up quickly in size. Chattering dust is now ready to be tested on civilian infrastructure.