6. Connecting large (~160 L) pressurized Dewar to equipment.

- Liquid cryogens are to be connected to equipment by a metal cryogen transfer hose and fittings

suitable for cryogenic use.

- Safety pressure relief valves rated for cryogenic service must be installed to prevent

over pressurization of the process equipment.

The exit port of the relief valve must be located in such a manner that cryogenic gasses or liquids released by

the valve will not be directed toward anyone working in the vicinity of the equipment.

- The gas relief valve on the dewar should be directed in such a way that it will not vent

gas in the direction of anyone walking by.

- If the gas valve on the dewar is connected to an external gas source to increase flow

from the liquid line, care must be taken to prevent the dewar from being over pressurized.

- The standard operating procedure for the process must be followed.

- Persons handling transfer lines should wear cryogloves if the lines are at

cryogenic temperatures. The specific PPE required for the process should be

specified in the hazard assessment for the area.

-

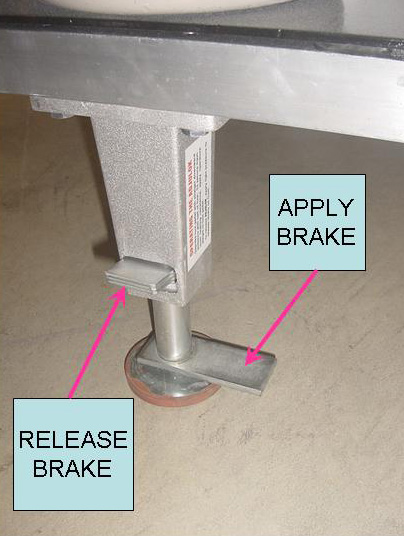

Large dewars should have brakes set when parked or when connected to equipment.

Some dewars have brakes on the caster like many common items.

Others have the brake shown to the right.

Step on the apply brake control firmly to set the brake, or stem on the release

brake control to remove the brakes.

The controls are positioned as shown to the right.

If the dewar doesn't have brakes, wheel chocks can be used.

Large dewars should have brakes set when parked or when connected to equipment.

Some dewars have brakes on the caster like many common items.

Others have the brake shown to the right.

Step on the apply brake control firmly to set the brake, or stem on the release

brake control to remove the brakes.

The controls are positioned as shown to the right.

If the dewar doesn't have brakes, wheel chocks can be used.

|

|