| |

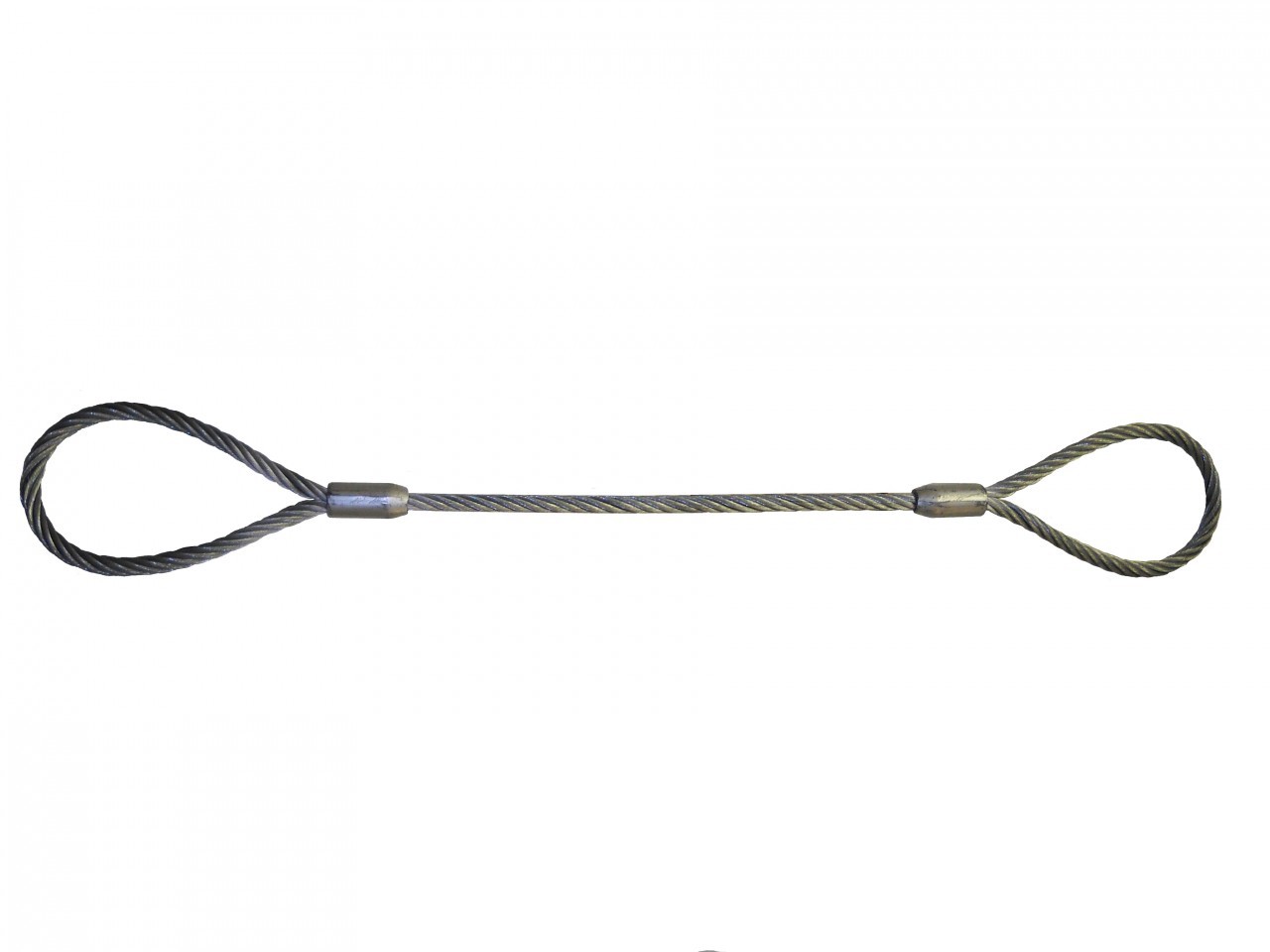

Wire rope should be inspected daily before it is used.

A wire rope sling must be discarded in the event of any of the failures listed below. |

| 1. |

there are Ten (10) randomly distributed broken

wires in one (1) rope lay, or

five (5) broken wires in one (1) strand in one (1) rope lay |

|

| 2. |

More than one broken wire at an end connection |

|

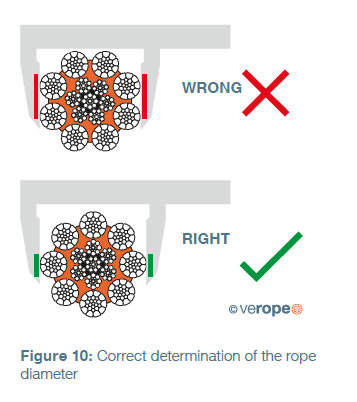

| 3. |

Reduction in rope diameter (1/3 or

more of the original wire diameter) |

|

| 4. |

Wire rope kinked |

|

| 5. |

Wire rope crushed |

|

| 6. |

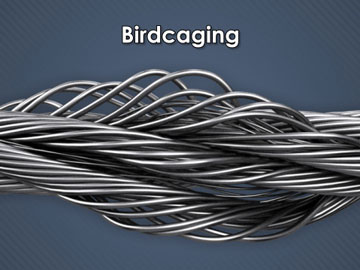

Wire rope birdcaging |

|

| 7. |

Wire rope core protrusion |

|

| 8. |

Wire rope heat damage |

|

| 9. |

Wire rope end attachments cracked, deformed, or worn |

|

| 10. |

Wire rope hooks or latches deformed or damaged |

|

| 11. |

Corrosion of the rope or end attachments |

|

| 12. |

Sling not marked with manufacturer and

rated load capacity for the type of hitch and angle |

|